CARBON GRAPHENE, 2D Graphene, 3D Graphene blocks, 3D Graphene Oxide, 3D Print Graphene, 3D Graphene Hydrogel, 3D Graphene Aquagel, 3D Graphene Aerogel, AeroGraphene, Sandaerograph.

SANDAEROCOMB, Hcar, Hybrid-electric combustion motor-generator bio-fuel exhauster, CO/CO2 laser mirror/lens flat box producing pure/metalized graphene, before a catalyser, filter and/or compressor to generate zero emission. SANDAEROCLAVE, bio-fuel algae, hydro-carbons, autoclave heater to produce graphene oxide to be laser treated to graphene, with secondary thermal energy production. Value of energy produced reduces energy cost to produce graphene.

CO2 laser mirror filter for combustion engine exhaustion, where it can be broken into C6 Graphene and O2 Oxygen, with C deposition receiving optional spray of resin and/or copper/silicon powder/sheet, to harvest graphene sheet or roll it up for graphene tube, wire, yarn and fabric. Animal/Plant Organic CH4 methane can also produce C6 Carbon Graphene and H2 Hydrogen. Animal CO2 can also be processed into Graphene and Oxygen.

CO2-CH4

Graphene

Sandaerograph

Carbon-Oxygen-Hydrogen

Combustion-Engine-Exhaust-Pollution

CO2-Graphene-Worth-Much-More-Than-Fuel

Solar-Pumped-Carbon-Lens-Mirror-Laser-Breaks-CO2

CVD-Carbon-Vapor-Deposition-Graphene-Sheets-Tube

CARBON FIBER FABRIC is already produced on a large scale at decreasing costs, however requiring several steps of heating at high temperatures and processing to form fibers, yarn and fabric.

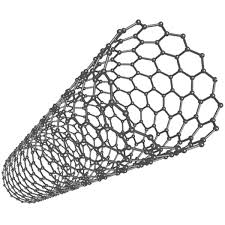

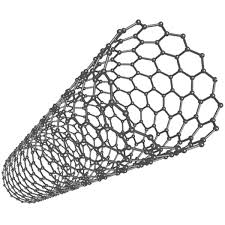

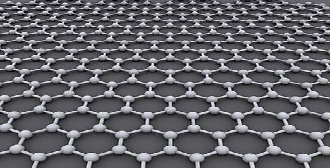

CARBON NANOTUBE is a nano single or multi layer rolled up fragmented single carbon hexagonal network.

GRAPHENE MACROTUBE and MACRORIBBON is a macro single or multi layer rolled up (tube) or flat (ribbon/fabric) graphene single carbon hexagonal network (or composite with carbon fabric, nanotubes, polymers etc), to replace steel cables, tubes, panels with over 10 times stronger material, capable for example, with a multi cable truss or ribbon formation, of full or interrupted connection to a 3-30k km space tower-elevator geosynchronous system, with or without a 100k km centrifugal counter-weight.

SANDAEROWIRE combines rolled up Graphene Macrotube with resin and metals as copper paper-sheets/spray/paint for high conductivity to replace heavy copper wires. Mega intertwined macrotubes can create a structural and conductive system for space elevators and space solar energy. Macro-Micro-Nano Sandaerowire wire and fabric can create structural and conductive surfaces for multiple applications, as motors and energy wiring replacing copper wires,

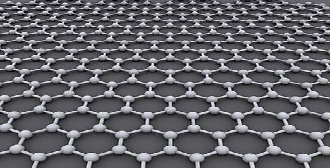

GRAPHENE FABRIC (made of one atom thick carbon hexagonal network) has the potential for lower cost and higher performance if it is also produced on a high industrial scale (from renewable products such as carbon dioxide, methane and sugars), with direct cloth formation with several layers of two dimensional carbon, with the addition of resins to obtain various properties, with less expenditure of energy and simpler process.

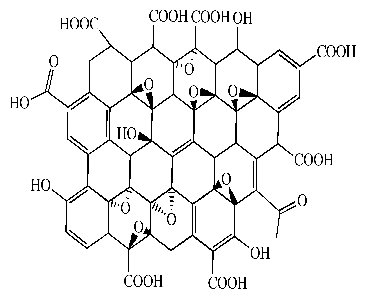

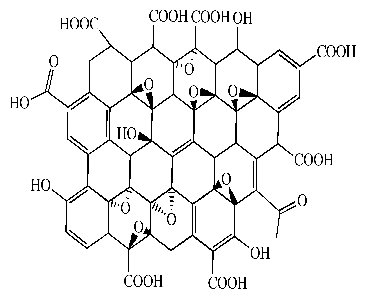

GRAPHENE OXIDE (Cx Ox Hx) (mono carbon layer soluble in liquid/ink) production of graphene cloth from CO2 (carbon dioxide), CH4 (methane) and/or fructose (C6 H12 O6), obtaining oxygen (O2), hydrogen (H2), water (H2O) as sub-products. Graphene is impermeable to all gases and liquids, sealing vacuum, while graphene oxide is permeable to liquid and water steam, can be used for formatting with subsequent expulsion of oxygen and hydrogen. CH4 + O2 = CO2 + 2H2 (energy); CO2 + CH4

(+ argon) (500 Celsius) = 2C + 2H2 (CVD: Chemical Vapor Deposition in a metal substrate); 2H20 = 2H2+ O2 (electrolysis); C6 H12 O6 (200 Celsius) = 6C + 6H20 (autoclave, high pressure chamber, heated to 150-200 degrees Celsius for 1-2 hours to form graphene oxide layer).

GRAPHENE FABRIC PRODUCTION in high industrial scale with a graphene oxide layer of paint blasted with a supersonic spray (rocket nozzle) on a metallic substrate (copper, nickel or platinum) with high temperature and subjected to laser to expel oxygen/hydrogen. Formation of subsequent layers of graphene with subsequent addition of resin/epoxy to obtain different properties (conduction or not of heat and/or energy; flexibility/hardness). These same techniques could in theory be improved to transform carbon dioxide (CO2), methane (CH4) and fructose (C6 H12 O6) directly in graphene.

GRAPHENE BLOCK PRODUCTION

(SANDAEROBLOCKS)

In the first method, graphene fabric is sewn and glued into Sandaeroblock shapes (sphere, cube, diamond, rectangular and triangular). Double cross graphene structure (four corners) containing halogen lamps is inserted in four parts connectable in the center. The air is heated and the shape inflated for resin application.

In the second method, more efficient, the step of production/sewing/inflation of the fabric is eliminated. Graphene is produced directly on an inflated nickel/copper fabric mold (with rounded corners) with supersonic (spray/rocket) or common(spray/brush/roller) application of graphene oxide. The kinetic force (impact), laser and/or high temperature will expel the oxygen and hydrogen atoms to leave only a layer of hexagonal network of carbon atoms.

Additional applications (or intercalated with other materials/resins) will form additional layers and close any fault in the network (Graphene with one layer of carbon atoms weighs 0.77mg/m2 and 1000 layers can form a network of less than 1g/m2 or less than 100g/m2 with resin, versus 300g/m2 of carbon fiber with resin). The resin is then applied, the double cross structure of halogen lamps is removed via 4 openings at the tips, the mold is deflated/withdrawn by the opening and the double cross structure is reinserted/reactivated to form solid monoblock without any sewing/glue.

The openings are sealed with air pump connected to air tube and electric wiring inside the double cross structure. The heated/pressurized air at 450 Celsius is partially removed to generate an internal density equivalent to 60% vacuum reducing/eliminating the block weight or generating floatation, depending on the size of the block and its altitude. The air can be almost completely evacuated at low pressure altitude, with the almost vacuum sustained by ultra lightweight rigid graphene structure. Vacuum/magnetic/mechanic sealed sliding doors/windows can be cut into the monoblocks.

GRAPHENE 3D PRINTING

(SANDAEROBLOCKS)

Laser, Digital Light Processing and Oxygen Management into a Graphene Oxide based liquid resin.

Cure/solidify resin expelling the Oxygen and filling the gaps with sequential layers of pure Graphene (2d carbon lattice) to form a full multi-layered 3D Sandaeroblock.

Macro 3D Carbon Graphene printer can mass produce ultra lite Sandaeroblocks to be filled with electrolysed hydrogen and vapor to become buoyant.

2D/3D Graphene sheet/foam, polymer hydrocarbons, bone cells, hydrogen can form low/zero/negative weight material self-repaired stronger/cheaper than steel for any engineering and can also conduct directly energy for living cells.

3D Sandaerograph/Aerographene: Algae (hydrocarbons/autoclave) to Graphene Oxide to Graphene Aquagel (aqua thermal/2 hours/160 celsius) or Graphene Hydrogel (+Polymer as PVA Polymer Vinyl) to Graphene Aerogel/Aerographene (dry freeze/24 hs, freeze to vacuum drying to remove water) to scaffold for complementing, composite materials/cells, as Hydrogen, sealed by 2D Graphene/Epoxi/Mylar/metal thin sheet as aluminum polymer.

Sandaerograph, 3D H2 AG, 3 Dimensions Hydrogen Aerographene has 0.163g/m3, generating 593.88 kg of buoyancy for a 5 meter radius Aerographene Sphere Module with carbon composite solar-wind fuel-cell motor-generator-propellers mounted on 6 sides of cube-sphere structure of Sandaeroship/Sandaerocar.

Ballast/power hydrogen/water/fuel cell/electrotrolysis, hydrogen+air in fuel cell creates water and energy for down-side propeller, solar-wind-fuel cell energy breaks water into hydrogen and released oxygen plus energy for propeller up-side.

Graphene fabric sewn, glued, inflated and formatted to apply resin

Copper fabric inflated mold for graphene formatting

Graphene oxide

application on mold

High temperature and/or

laser expel O2 and H2

Graphene monoblock with

carbon hexagonal network

Sandaerograph

H2-3D-Aero-Graphene

Ablock-Anet-Acar-Abot-Alife

Algae-Sugar-Cane-Hydrocarbon

Autoclave-Pressure-Heat-H2-Expel

Vacuum-Graphene-Oxyde-O2-Expel

3D-Nanotube-H2-Infuse-2D-Epoxy-Seal

SANDAEROWIRE

SANDAEROCOMB

SANDAEROCLAVE

Sandaerograph

Carbon-Graphene

Lasered-CO2-CH4-Deposition

Algae-Auto-Clave-Aero-Graphene-Oxide

Sandaeroblock-Superskin-Superbone-Applications

2D-Graphene-3D-Aerographene-3D-Graphene-Macro-Tube